Description

Antipodes Only the most recent film capacitors are designed, manufactured, and tested to meet or exceed the requirements of applicable IEC/ IS/ IEEE standards. In all film designs, the construction of an MV/HV capacitor is generally single (1) phase or three (3) phase with single/double/triple bushing termination. As its electrode, the capacitor is made of electrical grade double side hazy biaxially oriented PP film interleaved with soft annealed high purity aluminium foil. Under high vacuum, the capacitor is impregnated with electrical grade non-PCB insulating fluid.

Because of their low cost per kVAR, these capacitors are simple. a cost-effective source of reactive power in electric power systems for:

- Increasing the power factor

- lowering line losses

- Voltage drop is decreasing.

Power capacitors can be installed at a single station or in the factory—assembled, switched, or unswitched banks in a variety of configurations.

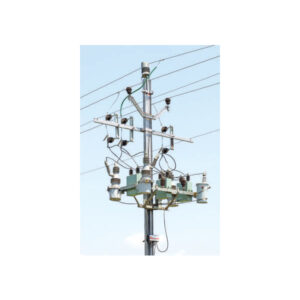

- Racks attached to poles

- Substation bank is now open.

- Bank on a pad

Zoe –

I’ve had a great experience with the HV CAPACITOR BANK. Its high voltage capacity, minimal losses, and improved tank rupture characteristics make it an excellent choice for both indoor and outdoor use.